Over-molding is revolutionizing industries by combining materials to enhance product design and functionality. This guide explains how dual material injection molding works, its benefits, and best practices, along with case studies and tips for material selection. Discover why over-molding is transforming product development.

What Is Over-Molding?

Over-molding is a custom injection molding process that involves adding a second material over or around a base material (also known as the substrate). The result? A single, cohesive part combining the unique properties of two distinct materials.

This technique is widely used in industries such as automotive, medical devices, consumer goods, and electronics to produce high-performance components.

Applications Across Industries

- Medical Devices: Over-molding is used to create surgical instruments with ergonomic grips or to seal medical-grade sensors.

- Automotive: Produces durable parts like soft-touch dashboard buttons or vibration-resistant engine components.

- Consumer Electronics: Combines soft-touch coatings on gadgets and wearables for comfort and design aesthetics.

- Power Tools: Adds non-slip grips on drills and hammers for improved handling and safety.

These applications show how over-molding not only enhances aesthetics but also adds functionality and durability to products.

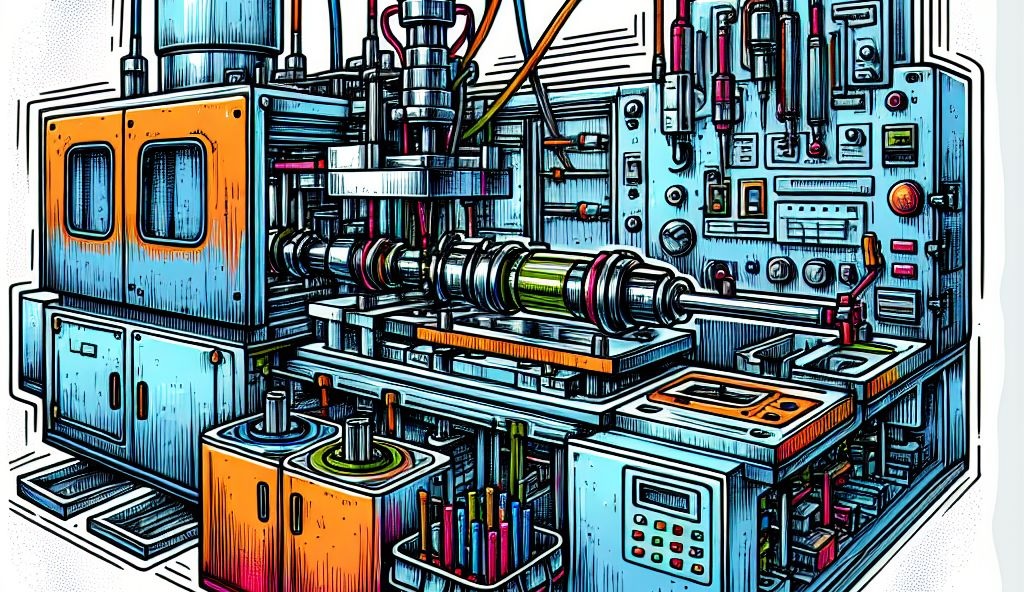

Understanding the Dual Material Injection Molding Process

The magic of over-molding lies in dual material injection molding — the process used to create over-molded parts. It involves using two different types of materials, often a rigid material for the substrate and a softer or more flexible material for the over-mold.

Here’s how it works step by step:

- Creating the Substrate: The first material is injected into a mold to create the substrate.

- Over-Molding: The second material is injected over or around the substrate. Bonding between the two materials occurs through heat and pressure.

- Cooling and Ejection: Once the component cools, it is removed from the mold and undergoes finishing if needed.

This precision-driven process requires careful planning, as compatibility between the materials and accurate mold design are critical for successful manufacturing.

Benefits of Over-Molding in Product Design

Over-molding offers manufacturers and designers a host of advantages.

- Enhanced Functionality: By combining materials with different properties, you can improve grip, thermal insulation, or shock absorption.

- Aesthetic Appeal: Over-molding allows for unique textures and colors, making products visually appealing without the need for secondary processes.

- Cost-Effectiveness: It streamlines the manufacturing process by eliminating the need for adhesives or assembly, reducing production costs and time.

- Durability: Over-molded parts often have stronger bonds and better resistance to wear and tear.

- Ergonomics: Soft-touch surfaces, such as rubber grips, improve user comfort and usability.

These benefits are why over-molding has become such a sought-after manufacturing solution.

Best Practices for Designing Over-Molded Parts

Getting over-molding right requires careful attention to design principles. Here are some best practices to follow:

- Focus on Bonding: Ensure the two materials are compatible for an optimal bond. This includes thermal compatibility and adhesive properties.

- Maintain Clearances: Account for the material shrinkage when designing the mold to ensure the secondary material aligns perfectly with the substrate.

- Draft Angles: Add suitable draft angles to enable easy ejection of parts during production without damaging the surface.

- Uniform Wall Thickness: Strive for uniform wall thickness to avoid defects and ensure consistent part quality.

- Design the Substrate with Features for Bonding: Use grooves, undercuts, or anchor points in the substrate design to mechanically secure the over-molded material.

Choosing the Right Materials for Over-Molding

Material selection plays a crucial role in ensuring a successful over-molding project. Consider the following when selecting materials:

- Compatibility: Check that the over-mold material adheres well to the substrate. Materials such as thermoplastic elastomers (TPEs) work well with rigid plastics.

- Application Requirements: Determine properties such as flexibility, durability, and insulation specific to your product. For example, medical-grade silicone is ideal for healthcare applications.

- Environmental Factors: Choose materials that can withstand conditions like heat, pressure, and UV exposure based on your product’s application.

- Testing and Prototyping: Always perform material testing and prototyping before full-scale production to ensure performance meets expectations.

What Does the Future Hold for Over-Molding?

The over-molding industry is rapidly evolving, thanks to advancements in materials science and manufacturing technologies like 3D printing.

Emerging trends include:

- Sustainable Materials: Increased demand for environmentally friendly materials, such as bio-based plastics.

- Innovative Applications: Growth in wearable technology, such as over-molded fitness trackers and hearing aids.

- Digital Twin Technology: Using virtual simulations to design and test over-molded parts before production.

These innovations promise to expand the capabilities and applications of over-molding, driving even more creativity and efficiency for manufacturers.

Explore the Possibilities of Over-Molding

Over-molding is revolutionizing the way we think about product design, offering unmatched flexibility, aesthetics, and performance. Whether you’re creating ergonomic consumer products, durable automotive parts, or precision medical devices, this technology can be your gateway to innovation.

If you’re ready to explore how over-molding can elevate your product designs, we’re here to help. Contact us today to discuss your project requirements and unlock the potential of dual material injection molding.

Conclusion

Now that you have a comprehensive understanding of over-molding and its benefits, it’s time to put this knowledge into practice. With the right materials, design considerations, and manufacturing techniques, over-molding can take your products to the next level. Embrace the possibilities of this technology and let your creativity soar!